Introduction

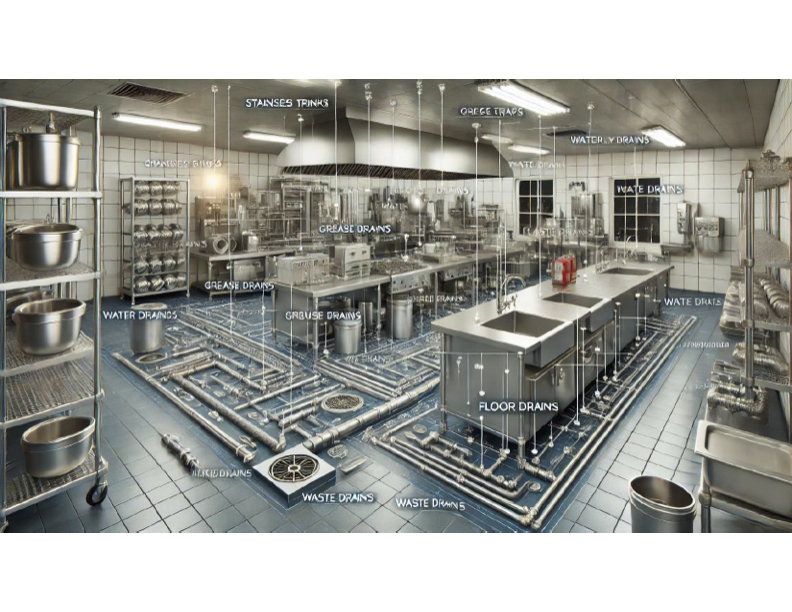

Plumbing and drainage systems in commercial kitchens play a crucial role in ensuring smooth operations, hygiene, and compliance with health regulations. Proper design and maintenance are vital for the safe and efficient management of water and waste in these high-demand environments.

1. Key Components of Plumbing in Commercial Kitchens

Commercial kitchen plumbing is more complex than residential setups due to the volume of water usage and waste production. Key components include:

- Water Supply Systems:

- High-capacity pipes to handle demand.

- Hot water systems with fast recovery times.

- Dedicated lines for potable and non-potable water.

- Drainage Systems:

- Sufficiently sized drains to prevent clogging.

- Properly installed grease traps to intercept fats, oils, and grease (FOG).

- Floor drains for spill management.

- Backflow Prevention:

- Devices to stop contaminated water from flowing back into the potable water supply.

- Specialized Fixtures:

- Wash sinks, hand sinks, and mop sinks.

- Pre-rinse sprayers and dishwashing equipment.

2. Regulatory Considerations

Compliance with local and national plumbing codes is essential for commercial kitchens. Important aspects include:

-

Health and Safety Codes:

- Adequate handwashing facilities with hot and cold water.

- Non-slip and waterproof flooring near drains.

-

Grease Management Regulations:

- Installation of grease traps as per local ordinances.

- Regular maintenance and documentation of grease interceptor cleaning.

-

Water Conservation Requirements:

- Use of water-efficient fixtures and appliances.

- Adherence to standards like EPA WaterSense.

3. Designing Plumbing and Drainage Systems

Efficient design is crucial to minimize downtime and ensure safety. Considerations include:

-

Layout Optimization:

- Strategic placement of sinks, dishwashers, and drains to reduce water transport distance.

- Clear separation of clean and dirty zones to prevent cross-contamination.

-

Drainage Slope:

- Proper slope (usually 1/4 inch per foot) to ensure smooth water flow.

-

Ventilation:

- Adequate venting for drains to prevent sewer gas leaks and pressure imbalances.

4. Grease Trap Systems

Grease traps are critical for maintaining the efficiency of drainage systems and preventing blockages:

-

Types of Grease Traps:

- Passive grease traps for smaller kitchens.

- Automatic grease removal devices for larger establishments.

-

Installation and Maintenance:

- Proper sizing based on kitchen output.

- Regular cleaning to prevent overflows and inefficiencies.

5. Maintenance Best Practices

Preventative maintenance reduces the risk of costly repairs and downtime:

-

Daily Inspections:

- Check for leaks, clogs, or unusual odors.

- Ensure sinks and floor drains are clear of debris.

-

Scheduled Cleanings:

- Grease trap and interceptor servicing.

- Flushing of drain lines to remove buildup.

-

System Upgrades:

- Replace old or undersized pipes and fittings.

- Update appliances with modern, water-efficient models.

6. Common Challenges and Solutions

-

Clogs and Blockages:

- Install strainers on sinks to catch debris.

- Use enzyme-based cleaners for organic buildup.

-

Grease Accumulation:

- Train staff on proper waste disposal practices.

- Invest in a high-capacity grease interceptor if needed.

-

Water Temperature Management:

- Ensure hot water systems meet demand without delays.

- Insulate pipes to maintain temperature consistency.

7. Future Trends in Commercial Kitchen Plumbing

-

Smart Plumbing Systems:

- Sensors for leak detection and water usage monitoring.

- Automated grease removal technologies.

-

Sustainability Innovations:

- Recycling of greywater for non-potable uses.

- Integration of rainwater harvesting systems.

-

Improved Hygiene Standards:

- Touchless faucets and fixtures.

- Enhanced backflow prevention mechanisms.

Conclusion

Proper plumbing and drainage systems are foundational to the success of any commercial kitchen. By prioritizing efficient design, regulatory compliance, and regular maintenance, businesses can ensure a safe, sustainable, and hassle-free operation. Investing in high-quality systems and staying informed about industry advancements will keep kitchens running smoothly and profitably.