Introduction

Efficient workflow and ergonomics are critical in commercial kitchens, where productivity, safety, and staff well-being significantly impact the quality of food and service. A well-designed kitchen layout, coupled with an ergonomic approach, minimizes unnecessary movement, reduces fatigue, and ensures a seamless flow of operations. This guide explores key principles, design considerations, and best practices for optimizing workflow and ergonomics in commercial kitchens.

1. Importance of Workflow Optimization

- Time Efficiency: Streamlined workflows save time in food preparation, cooking, and service.

- Consistency: Organized processes ensure uniform quality across dishes.

- Safety: Reduces risks associated with slips, trips, and other workplace hazards.

- Employee Satisfaction: A logical, ergonomic setup fosters a better work environment and reduces fatigue.

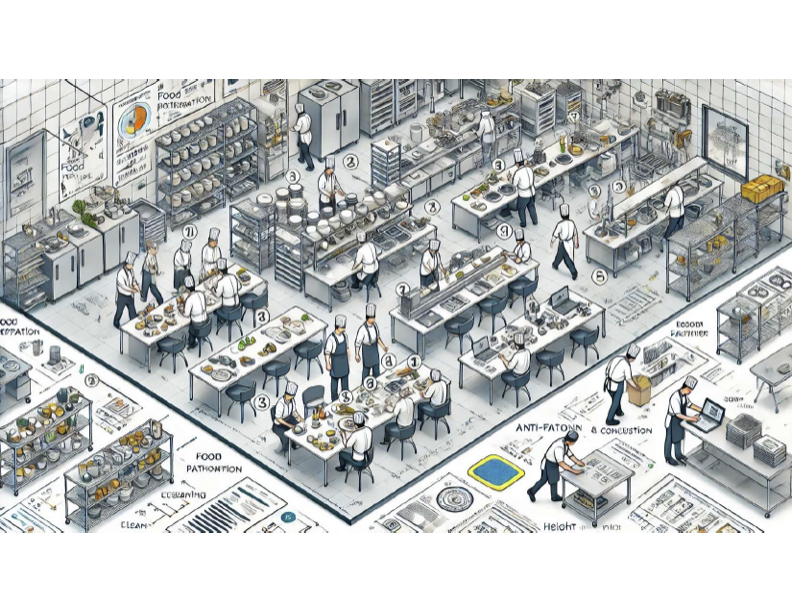

2. Key Principles of Workflow in Commercial Kitchens

- Zoning:

- Separate stations for preparation, cooking, plating, and washing to avoid cross-traffic.

- Logical proximity of zones to related tasks or equipment (e.g., sink near prep area for washing produce).

- Linear Flow:

- Arrange workstations in a linear or circular flow to minimize backtracking.

- Maintain a logical sequence: storage → prep → cooking → plating → service.

- Minimizing Movement:

- Frequently used tools and ingredients placed within arm’s reach.

- Clear pathways to avoid obstruction.

- Team Collaboration:

- Design spaces that allow multiple chefs to work efficiently without overcrowding.

3. Ergonomics in Kitchen Design

- Workstation Height:

- Adjustable counters or appropriately sized work surfaces for varied staff heights.

- Ideal prep counter height: 36-39 inches (adjust based on chef preferences).

- Reachable Storage:

- Overhead shelves and lower cabinets accessible without straining.

- Use pull-out drawers or racks for easy access to items.

- Flooring:

- Non-slip, cushioned flooring to reduce foot strain and prevent accidents.

- Lighting:

- Bright, shadow-free lighting at workstations to prevent eye strain.

- Ventilation:

- Adequate air circulation to maintain comfort in high-temperature environments.

4. Common Commercial Kitchen Layouts

- Assembly Line Layout:

- Ideal for high-volume production, especially in fast food or catering kitchens.

- Island Layout:

- Centralizes equipment for efficient team collaboration.

- Zone Layout:

- Divides space by task, suitable for varied menu offerings.

- Open Kitchen Layout:

- Combines functionality and aesthetic appeal, allowing customers to view the process.

5. Technology and Equipment for Workflow and Ergonomics

- Smart Appliances:

- Equipment with programmable settings for consistency and reduced manual effort.

- Energy Efficiency:

- Invest in appliances that save energy and reduce kitchen heat levels.

- Automation:

- Food processors, conveyor systems, and automated dishwashers for time-saving.

- Portable Tools:

- Lightweight and multi-functional gadgets to reduce physical strain.

6. Best Practices for Implementation

- Involve Staff:

- Gather input from chefs and kitchen staff during the design phase.

- Regular Audits:

- Conduct periodic checks to identify inefficiencies or ergonomic issues.

- Training:

- Educate staff on proper equipment use and ergonomic techniques (e.g., safe lifting practices).

- Maintenance:

- Ensure all equipment is in working order to prevent workflow interruptions.

7. Case Study: Ergonomic Improvements in a Commercial Kitchen

- Challenge:

- A restaurant faced bottlenecks during peak hours due to poorly positioned stations and insufficient storage.

- Solution:

- Reorganized the kitchen into zones, installed additional prep tables, and upgraded to ergonomic shelving.

- Outcome:

- 30% reduction in prep time and improved employee satisfaction scores.

Conclusion

Optimizing workflow and ergonomics in commercial kitchens not only enhances operational efficiency but also creates a safer, more enjoyable working environment for staff. By focusing on thoughtful design, innovative technology, and practical practices, kitchens can achieve peak performance and ensure long-term success.