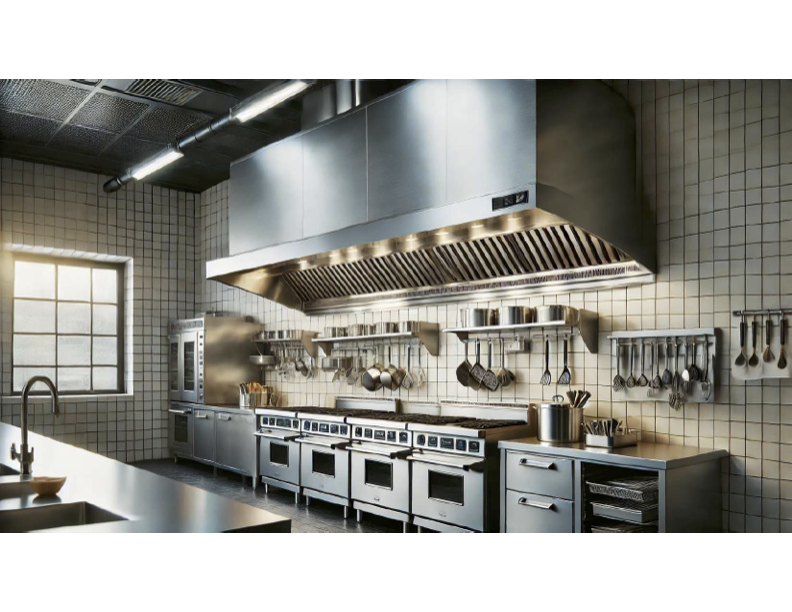

Wall-mounted commercial kitchen hoods are essential for restaurants, food preparation areas, and other commercial kitchens, where they ensure air quality, safety, and hygiene. These hoods are typically installed directly against a wall above cooking equipment to capture and remove smoke, grease-laden vapors, and other airborne contaminants generated during cooking. Here’s an in-depth look at key aspects of wall-mounted commercial kitchen hoods:

1. Types of Wall-Mounted Commercial Kitchen Hoods

- Type I Hoods: Designed specifically for capturing grease-laden vapors from appliances like fryers, grills, and ovens. They usually come equipped with grease filters and require a more robust exhaust system.

- Type II Hoods: Primarily used for heat, steam, and odor control, without dealing with grease. Suitable for applications involving non-grease producing equipment, like dishwashers and pasta cookers.

2. Core Functions and Benefits

- Air Quality Management: By capturing smoke, grease, and other contaminants, wall-mounted hoods improve the indoor air quality, helping to maintain a clean kitchen environment and reducing respiratory risks for kitchen staff.

- Temperature Control: These hoods reduce excess heat generated from cooking appliances, which helps regulate kitchen temperatures and contributes to employee comfort.

- Fire Safety: Many hoods are equipped with fire suppression systems or can be integrated with one, reducing the risk of grease fires.

- Compliance with Regulations: Commercial kitchens must meet health and safety codes. Properly installed wall-mounted hoods ensure compliance with local regulations and reduce the risk of fines.

3. Key Components

- Filters: Grease filters (typically stainless steel baffle filters) trap grease particles to prevent buildup in the ductwork. Filters need regular cleaning or replacement.

- Fans and Blowers: Exhaust fans are crucial for removing air contaminants. The fan's power depends on the kitchen’s size and cooking load.

- Lighting: Built-in lighting provides adequate visibility for safe and efficient cooking.

- Control Panels: Most modern hoods come with control panels for easy operation, allowing adjustments to fan speed and lighting as needed.

4. Installation Considerations

- Clearances and Dimensions: The size of the hood should correspond with the cooking equipment and kitchen layout. Clearances from walls, ceilings, and cooking appliances are crucial for safety and compliance.

- Ductwork: Effective ducting is essential for directing exhaust to the outside. Proper ductwork design minimizes backflow and ensures efficient exhaust.

- Fire Suppression Systems: It’s common to integrate a fire suppression system with commercial hoods, automatically releasing extinguishing agents in case of a fire.

5. Maintenance Requirements

- Regular Cleaning: Grease buildup poses fire hazards, so frequent cleaning of filters and surfaces is essential.

- Inspection and Repairs: Regular inspections for wear on filters, fans, and ducting help maintain functionality and efficiency. Timely repairs can prevent costly breakdowns.

- Compliance Checks: Many jurisdictions require periodic inspections to ensure that the kitchen hood system meets local codes and safety standards.

6. Choosing the Right Hood for Your Kitchen

- Cooking Equipment and Volume: High-output kitchens require larger hoods with higher exhaust capacities. The type of cooking equipment impacts the choice of Type I or Type II hoods.

- Ventilation Requirements: Local codes often dictate ventilation requirements, including minimum air change rates and specific exhaust rates for different cooking equipment.

- Budget and Energy Efficiency: Energy-efficient models may have a higher initial cost but provide long-term savings by reducing energy consumption.

7. Innovations in Commercial Kitchen Hoods

- Eco-Friendly Features: Some models are designed to consume less power or even come with built-in energy recovery systems.

- Smart Controls: Advanced models offer smart controls that adjust fan speeds based on cooking intensity, optimizing energy use.

- Self-Cleaning Systems: Self-cleaning hoods reduce the manual cleaning requirements, improving hygiene and efficiency.

Conclusion

Wall-mounted commercial kitchen hoods are a vital investment for any commercial kitchen, balancing functionality with safety and compliance. When selecting a hood, consider factors such as the kitchen layout, type of cooking equipment, and local regulations to find a system that meets your kitchen’s unique demands. With proper installation, maintenance, and smart use, these hoods will ensure a safer, cleaner, and more efficient cooking environment.

These insights will help in choosing the most suitable wall-mounted hood, tailored to your kitchen’s needs and ensuring a safe and pleasant work atmosphere.