If you’re planning a commercial kitchen, don’t start with the menu — start with the layout. A smart, spec-driven layout doesn’t just make the kitchen look good on paper — it keeps your staff safe, your service fast, and your operation profitable. Here's what you need to get right.

1. Know the Core Work Zones

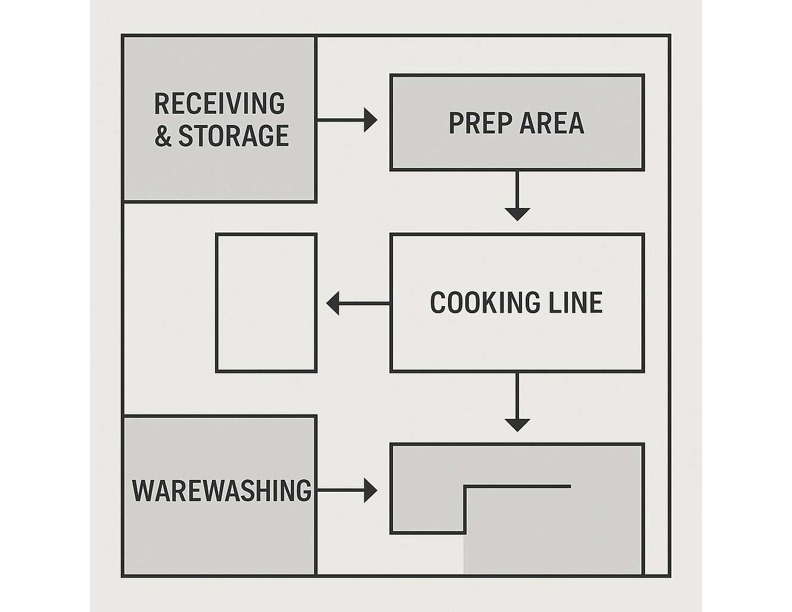

A commercial kitchen should flow like an assembly line. That means defining and separating these core zones:

-

Receiving & Storage: Place this near the back entrance. Include dry storage, refrigerated storage, and freezer access.

-

Prep Area: Should be close to storage and equipped with sinks, cutting surfaces, and mixers.

-

Cooking Line: The heart of the kitchen. Keep hot equipment grouped together and ensure solid ventilation.

-

Service/Pass: Where food transitions from kitchen to server. Needs heat lamps, ticket rails, and smooth access.

-

Warewashing: Keep it away from prep and cooking areas. It should connect to both the kitchen and the dining room.

2. Follow the 5 Flow Rules

Keep these five flows tight and uninterrupted:

-

Food flow – from receiving to storage to prep to cooking to service.

-

Staff flow – employees shouldn’t have to cross paths or backtrack.

-

Equipment flow – heavy equipment shouldn’t block walkways or need to be moved often.

-

Waste flow – dirty dishes and garbage need their own path out.

-

Air flow – good HVAC isn’t optional. Steam, grease, and heat must be vented effectively.

3. Size Matters — But Efficiency Rules

You don’t need a massive kitchen. You need one that works. Here's a general guide:

-

Kitchen to dining ratio: 30% kitchen, 70% front-of-house.

-

Minimum kitchen size: About 200 sq ft for fast casual, 500–1000+ sq ft for full-service.

-

Aisle width: At least 42" in prep areas, 60" in main traffic zones.

Plan for the right number of stations, not just square footage. Tight spaces can work if the layout eliminates wasted motion.

4. Spec the Right Equipment — and Place It Right

Every piece of equipment should serve a specific need and fit the layout. Key points:

-

Line cooking equipment (grills, fryers, ranges) should be under the same hood.

-

Prep sinks and dish sinks must comply with health codes — usually a 3-compartment sink minimum.

-

Cold storage should be accessible but not disrupt traffic flow.

-

Work tables should be stainless steel, with undershelves or casters for flexibility.

Also: double-check clearances. Commercial equipment needs space around it for cleaning, heat dissipation, and code compliance.

5. Build for Safety and Code Compliance

Your layout isn’t just about speed — it’s also about safety. That means:

-

Fire suppression systems for all cooking equipment.

-

Non-slip flooring in all kitchen areas.

-

Proper drainage to avoid standing water.

-

Adequate lighting — especially over prep and cooking areas.

-

Hands-free handwashing sinks within reach of every station.

Work closely with a health inspector or consultant before finalizing plans — reworking a layout after construction is expensive.

6. Tech and Utilities Planning

Plan for:

-

Electrical outlets: Each appliance has a spec. Don’t guess.

-

Gas lines: Know your BTU loads and pipe sizes.

-

Water supply: Pressure and temp must meet code.

-

Point-of-sale and communication tools: These should be hardwired or reliably wireless in the service areas.

Don’t leave this to the last minute. Utility locations affect where you can place equipment, so they must be integrated into the layout from the beginning.

Final Thoughts

Planning a commercial kitchen layout isn’t glamorous, but it’s the foundation of everything that happens in your restaurant. The right specs can save thousands in labor, prevent food safety disasters, and help your team move like clockwork. Don’t just fill a space — design a system that works.