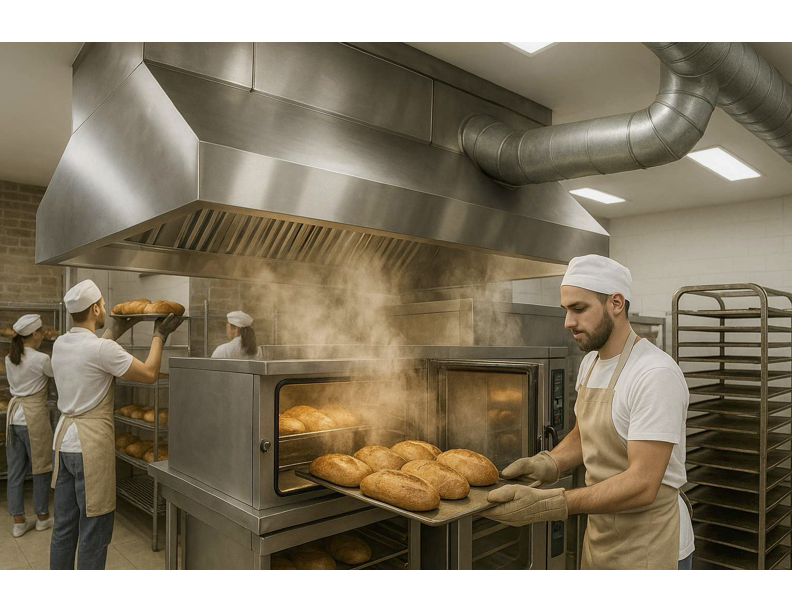

When most people think of bakeries, they imagine the smell of fresh bread, croissants, and pastries wafting through the air. But behind that cozy image is a hot, high-output kitchen filled with ovens, mixers, and non-stop activity. And where there's heat, there’s the need for proper ventilation.

If you're running a bakery—or planning to open one—ventilation equipment isn’t just a box to check. It’s mission-critical. Here's what you need to know to make smart decisions that keep your team safe, your product quality high, and your operation code-compliant.

Why Ventilation Matters More in a Bakery

Unlike a typical restaurant kitchen that deals with mixed cooking equipment, bakeries rely heavily on long-running ovens and proofers. These crank out serious amounts of:

-

Heat

-

Steam

-

Odors

-

Particulates (like flour dust)

Without good ventilation, that combination can make your workspace unbearable and even hazardous. Poor air quality affects everything from employee health to dough performance. Excess heat and humidity can also mess with fermentation and ruin consistency.

The Core Components of a Bakery Ventilation System

Here’s a breakdown of the essential gear:

1. Exhaust Hoods

You need hoods over your ovens to capture rising heat and vapors. Depending on your setup, you'll choose between:

-

Type I Hoods – For equipment that produces grease-laden vapors (less common in pure bakeries but needed if you’re frying anything).

-

Type II Hoods – For heat and moisture removal, ideal for ovens and proofers.

Make sure the hood size and capture velocity match your oven output. Undersized hoods won’t cut it.

2. Make-Up Air Units (MAUs)

Exhaust systems pull air out. Make-up air units bring fresh air in to balance the pressure. Skip this, and you'll end up with doors slamming shut, drafts, and unhappy bakers gasping for air.

Bonus: Properly tempered make-up air helps maintain temperature and humidity control.

3. Ductwork and Fans

High-efficiency fans and well-sealed ductwork are key. Inline fans can reduce noise, and variable-speed motors let you adjust airflow based on time of day or oven load.

4. Air Filtration and Scrubbers

If you're in a dense urban area or close to other businesses, installing odor-control filters or scrubbers can reduce smell complaints and keep neighbors happy.

Special Considerations for Bakeries

-

Flour Dust: It's highly combustible. Your system should avoid creating airborne concentrations and meet NFPA standards if you’re handling flour in large volumes.

-

Humidity Control: Proofing and baking generate a lot of moisture. Too much can cause condensation and mold growth. Ventilation must address both humidity and airflow.

-

Noise: Ventilation systems can be loud. Use sound-dampening materials or remote fan placement to reduce noise in front-of-house or open-kitchen designs.

Common Mistakes to Avoid

-

Ignoring Local Codes: Health and fire codes vary. Always work with a licensed HVAC specialist familiar with commercial baking operations and local rules.

-

Overlooking Maintenance: Filters, fans, and ducts need regular cleaning. Flour buildup isn’t just a fire hazard—it chokes your system's efficiency.

-

Overcooling the Workspace: Excessive air exchange can cause temperature swings, which is terrible for fermenting dough. Aim for balance.

Final Thoughts

Investing in the right ventilation equipment isn’t glamorous—but it’s foundational. Get it right, and your bakery runs smoother, your staff stays safer, and your croissants rise just how they should.

Before you fire up that first oven, make sure your air game is tight. Because in the bakery business, what’s in the air matters as much as what’s in the dough.